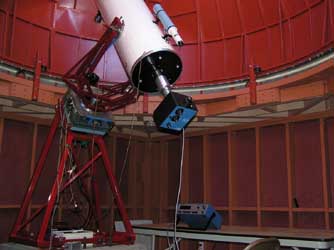

This is a 1976 photo of my friend, Master Machinist Bill

Loumaster, and the

This is a 1976 photo of my friend, Master Machinist Bill

Loumaster, and thetelescope he designed and built. Bill got more enjoyment making it than using

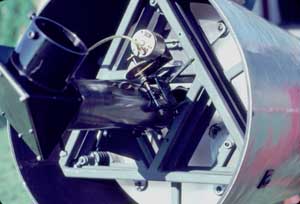

it and so he sold it to me around 1975 or 1976. The 12.5" f15 Dall-Kirkham

mirror set were purchased from Coulter Optics around 1974. The design of

the telescope is entirely his and he made everything himself from the tripod to

the OTA, The telescope tube was made by rolling fiberglass cloth layers to a

wall thickness of 3/16th of an inch. He rigged up a frame for the cloth that

continuously rotated during curing so that the tube walls would not sag. He

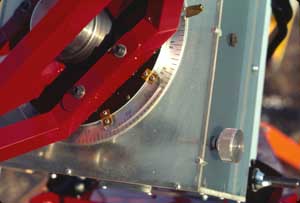

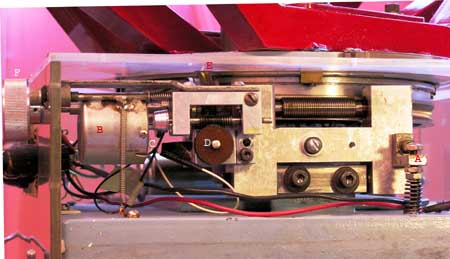

made the 9" worm gear and worm from, if I remember correctly, out of

stainless steel and lapped them. Bill won a Unique Design award at the 1983

Riverside Telescope Maker’s Conference.

After getting the telescope I replaced the finder and beefed up the fork arms.

It was mounted in my permanent observatory for about 15 years and then in

2006 I replaced it with a 16" Meade LX200R.